Testing

Apparatus Fire Pump Testing

The apparatus fire pump test is conducted on pumps found in fire engines, trucks and water tenders. It can be performed using water drawn from a fire hydrant or from a draft source, such as a drafting pit, lake or river.

How often do I test a fire pump apparatus pump?

Annually. According to NFPA 1911, “Service tests are conducted at least annually and whenever major repairs or modification to the pump or its components have been made.”

Where do I find more information on apparatus fire pumps?

Hydrant Flow Testing

Hydrant flow tests are conducted to determine water availability in planning for firefighting activities, fire sprinkler systems or domestic water demand. The tests are also useful in determining the general condition of the water distribution system by detecting closed valves or wall deposits. A well-maintained water system enables firefighters to extinguish flames and prevent large-scale damage or loss of life.

HOW OFTEN DO I TEST A HYDRANT?

AWWA recommends flow testing all areas at least every 10 years (AWWA M17).

NFPA requires flow testing of underground and exposed piping at least once every 5 years (NFPA 291).

WHERE DO I FIND MORE INFORMATION ON HYDRANT FLOW TESTING?

NFPA 291 — Recommended practice for fire flow testing and marking of hydrants

LinkAWWA Manual 17 — Installation, field testing, and maintenance of fire hydrants

The Hose Monster Company Catalog — Section on Fire Flow Testing includes how-to instructions and more

LinkHydrant Flow Test Calculator — Calculates the rated capacity at 20 psi for a fire flow test.

LinkFAQs on Hydrant Flow Testing

LinkFire Pump Testing

Fire pumps provide water supply to fire sprinkler systems where the water supply pressure is too low or nonexistent. The field acceptance test is conducted on newly installed pumps and demonstrates that all the fire pump unit components perform according to manufacturers’ specifications as well as proving that the water supply is adequate. The annual fire pump flow test can identify deterioration of the fire pump or impairments to the water supply.

How often do I test a fire pump?

According to NFPA, fire pumps are flow tested after initial installation according to the field acceptance test procedure (NFPA 20). Thereafter, the annual fire pump test is performed (NFPA 25).

The Hose Monster® fire pump test system

The Hose Monster will make your job of testing pumps safe, simple and accurate. Because of the unique thrust-canceling design of the Hose Monster, tests can be conducted on an established lawn or a gravel surface without causing damage. The Hose Monsters are FM Approved.

Software for Fire Pump Teesting

Fire Pump Tester Software (FPT) allows fire protection contractors, fire protection engineers, and building managers to collect fire pump test data in a professional and comprehensive format. FPT eliminates the need for users to perform complicated tasks such as calculating flow rates, calculating performance-corrected flow, and graphing flow curves. The user just enters their data, and the program performs all the hard work.

Where do I find more information on fire pumps?

Standpipe and PRV Testing

A standpipe is the vertical piping that connects fire sprinkler systems and hose stations between multiple floors. It is common to see standpipes in stairwells of high-rise buildings. A rooftop standpipe test verifies the water supply, pump and piping at the topmost part of the system is accurate.

In the past, the only way to perform rooftop standpipe tests was with playpipes and hand-held pitots. Safely securing playpipes and controlling discharge water to avoid interfering with pedestrian and vehicle traffic was a significant challenge, typically requiring that testing be in the early morning hours. The introduction of the Hose Monster® line of equipment changed all that. The Hose Monster neutralizes the dangerous thrust and controls discharge water on the rooftop while minimizing hazards to pedestrians and property below.

In some cases, discharging the water can be a challenge since you may be in a stairwell or basement. The In-Line Pitotless Nozzle™ can take flow-rate measurements at the valve, allowing you to run hose or piping to a drain or down several flights of stairs.

HOW OFTEN DO I TEST A STANDPIPE OR PRV?

Every five years. According to NFPA 25, “A flow test shall be conducted every five years at the hydraulically most remote hose connections of each zone of an automatic standpipe system to verify the water supply still provides the design pressure at the required flows.”

WHERE DO I FIND MORE INFORMATION ON STANDPIPES AND PRVs?

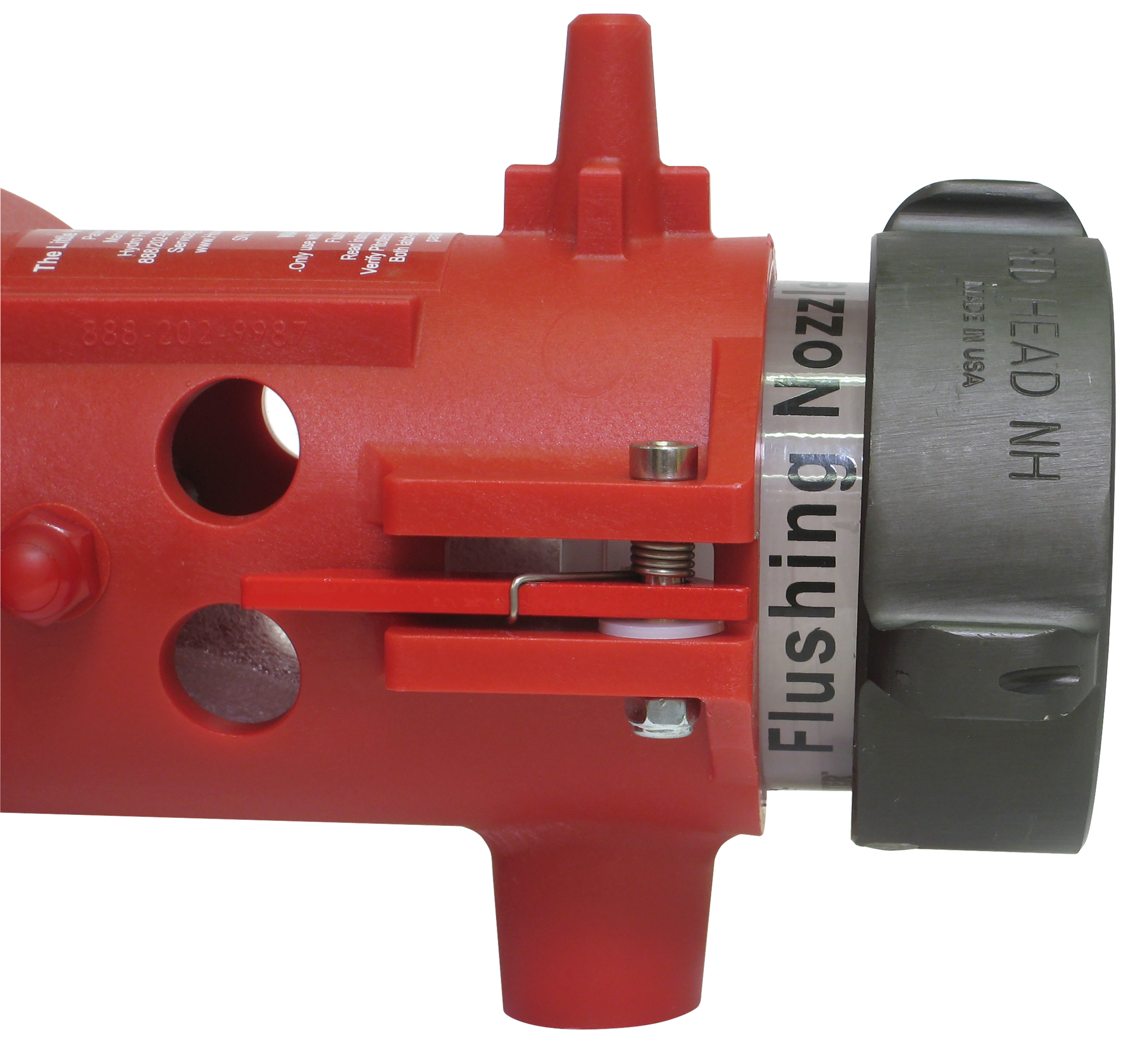

Flushing

Conventional Hydrant Flushing

Conventional flushing is the practice of simply opening one or more fire hydrants and allowing the water to run until sediment or poor-quality water is removed. Conventional flushing differs from unidirectional flushing in that no valves are closed to increase the velocity of water through the mains, making it less effective at cleaning the mains. Hydrant flushing differs from Hydrant Flow Testing because conventional flushing does not require any flow-rate measurements and does not measure water supply. Hydrant flushing is part of the hydrant’s annual maintenance procedure described in NFPA 25 and AWWA M17.

HOW OFTEN DO I FLUSH HYDRANTS?

NFPA 25 requires all hydrants be fully opened and given an inspection on an annual basis. Flow and pressure readings are not required during this annual inspection.

WHERE DO I FIND MORE INFORMATION ON HYDRANT FLUSHING?

Unidirectional Flushing

Unidirectional flushing is the process of cleaning the water mains of a water distribution system by flowing water in one direction through the mains. This is accomplished by closing specified valves and by flushing strategically located hydrants. By closing specified valves, the velocity of water through the mains is increased. The main purpose of unidirectional flushing is to improve water quality within the distribution system. It is generally considered to be more effective at removing sediments than conventional flushing and also uses less water.

WHERE CAN I FIND MORE INFORMATION?

AWWA Maintaining Water Distribution-System Quality

AWWA Research Foundation — Investigation of Pipe Cleaning Methods

Dechlorination

Dechlorination

When chlorinated water is discharged in a flow test, it can drain into lakes, rivers and streams and harm aquatic life. According to AWWA, “Water released into the environment shall meet the applicable federal, state, provincial or local regulatory agency’s residual chlorine limit.” Your authority-having jurisdiction provides dechlorination requirements.

How does it work?

A portion of the water flowing through the Dechlor Demon™ is diverted through the bypass into a mixing tank, where it is combined with a concentrated dechlorinating agent. The bypass flow is controlled by a precision indicating valve. The concentrate is reintroduced into the Dechlor Demon and hose, where it continues to mix with the flowing water. The chlorine is neutralized by the time it exits the hose.

WHERE DO I FIND MORE INFORMATION ON DECHLORINATION?

ANSI/AWWA C655-09 standard for field dechlorination

Product Manual for Dechlor Demon